More time for the essentials - thanks to automation solutions from coboworx

Thanks to our rentable robot solutions, you can automate your production quickly, safely and without risk. Every solution is the result of over 100 years of expertise in robotics and automation being put into practice. Take advantage of it! Trusted by these leading SMEs and many more:

Heavy Wine Boxes, Smart Solution: Automation in the Winery

Industry

Food production

Workpieces

Cartons

Revenue

> €4 million

Challenge

At the winery, numerous cartons each containing six bottles of wine had to be manually stacked onto pallets every day – layer by layer, for many hours. This meant physically demanding, repetitive work for employees and slowed down operations, especially during peak season. In an industry characterized by seasonal peaks and limited personnel, a solution was needed to relieve staff and make the process more efficient in the long term.

Results

Employees relieved and meaningfully redeployed in bottling

Rapid integration of the solution within just a few days

More ergonomic workplace and more efficient workflows

Fresh Start in Automation at Gartenfrisch Jung

Industry

Food Production

Working pieces

Crates

Revenue

€100 million

Challenge

At Gartenfrisch Jung, hundreds of plastic crates filled with fresh salads and vegetable products had to be manually stacked up to more than two meters high every day. This meant monotonous, physically demanding work for employees and posed major challenges for the team during peak order periods – especially in an industry where it is difficult to find additional skilled workers.

Results

Entry into automation without investment risk

One employee per line reassigned to other tasks

Significant physical relief for the team

"The robot takes over the monotonous heavy work – it’s a huge relief for our employees. The operation is simple, and minor issues can be resolved quickly on our own. That secured acceptance within the team right from the start."

Fabian Zeller, Deputy Operations Manager

Gartenfrisch Jung GmbHHeavy loads, smart solution: Robotics at Steinlando

Industry

Mineral raw materials

Product

Cartons

Revenue

< €10 million

Challenge

At Steinlando, large volumes of heavy packages—mostly 25 kg sacks in cartons—must be packed and palletized every day. With a small warehouse team of just ten employees, this meant not only high physical strain, but also limited flexibility during staff shortages and seasonal peaks.

Results

50% less personnel required with the same output

High process reliability and precision in palletizing

Significant physical relief for the team

"Especially with our small warehouse team of just ten people, the system is a real asset – it makes us significantly more resilient in day-to-day operations."

Philipp Vogler, Managing Director

Steinlando GmbH + Co. KG1 ton per hour – cobot takes over palletizing at Panifactum

Industry

Food production

Product

Cartons

Revenue

> €1.5 million

Challenge

Hofmann Lowcarb Food GmbH—also known as Panifactum—produces high-quality low-carb baked goods and has faced the challenge of meeting growing demand in a confined production space. A compact cobot solution now automates the palletizing process – safe, space-saving, and easy to operate.

Results

Employees relieved and redeployed to higher-value tasks

Increased production efficiency

Palletizing in just 3 m² of floor space

“This is our first step into automation – and a highly successful one. Our employees are thrilled – the robot has become a valued member of the team.”

Matthias Hofmann, Managing Director

Hofmann Lowcarb Food GmbHVerival frees up 2 employees with palletizing automation

Industry

Food production

Product

Cartons

Revenue

> €8.9 million

Challenge

Verival Bio faced a bottleneck in its packaging process: manual palletizing of cartons led to downtime, low employee motivation, and inconsistent stacking results – all while dealing with a skilled labor shortage and increasing international demand. Today, a compact palletizing robot from coboworx automates the process reliably and efficiently – with minimal space requirements and no major adjustments to existing operations. A true win for both productivity and workplace ergonomics.

Results

2 employees relieved & successfully reassigned to more complex tasks

Fast return on investment – full payback within just 1.5 years

Improved production quality through reduced transport damage

“Automating with coboworx has made our production not only more cost-effective, but also improved quality and relieved our employees. For us, it was an absolutely worthwhile step forward.”

Stefan Lindauer, Executive Management

Verival Bio GmbH50% efficiency increase thanks to automation at Otto Oehme

Industry

Chemical Production

Product

Cartons

Revenue

> €16 million

Challenge

Otto Oehme GmbH faced the challenge of eliminating the last manual step in an otherwise largely automated production: palletizing heavy cartons of 1-liter bottles. The physical strain led to staff absences and bottlenecks – especially during peak order volumes. A compact robot cell now automates the process – cost-efficient, reliable, and ergonomically sound.

Results

50% increased productivity

Ergonomic relief for employees

Implementation without high upfront investment

"The solution runs reliably, and team morale has improved – the fear of having to manually stack 15 pallets a day is a thing of the past."

Carlos Oehme, Managing Director

Otto Oehme GmbHCobot relieves employees and ensures a reliable process at f&f

Industry

Food production

Product

Cartons

Revenue

> €79 million

Challenge

f&f SA/AG faced the challenge of automating the manual palletizing of 7- and 14-kg egg cartons to meet rising production demands. Especially during peak times, such as around Easter, the team reached its limits with manual handling. The mobile palletizing cell from coboworx enabled efficient automation with 600 cartons per hour and high flexibility.

Results

Ensured process reliability at 600 cartons per hour

Ergonomic relief for employees

Increased efficiency by freeing up qualified personnel

30 tons of workload reduction per shift at DEIKRA-FUTTER

Industry

Agriculture

Product

Bags

Revenue

> €35 million

Challenge

In the production line of Deikra Futter GmbH, manually palletizing around 30 tons of feed bags per day placed a huge strain on employees. Limited space made it difficult to expand production. Managing Director Matthias Vogt chose to automate the process to relieve staff and improve efficiency.

Results

Ergonomic relief for employees

Increased production efficiency

Increased flexibility for different bag formats

"The coboworx team supported us every step of the way and always put our needs first. Communication was always on equal footing. That was exactly the human approach we were looking for."

Matthias Vogt, Managing Director

Deikra Futter GmbHStreamlined production of 400 units per hour at Wollenhaupt

Industry

Food production

Product

Cartons

Revenue

> €48 million

Challenge

Manual palletizing at Wollenhaupt Tee GmbH was particularly error-prone with high pallets, resulting in unstable loads and damaged products. Additionally, the physical strain of constant bending and lifting with a high order volume added to the challenge. A coboworx automated robotic solution now ensures stable pallets, noticeable relief, and greater efficiency.

Results

Quality increase in production

Increase of production efficiency

Employees are freed up for more complex tasks

"This technology not only saves us time; it allows us to reduce the workforce on strenuous tasks and shift efforts to areas that require more human oversight."

Marcel König, Machine and plant operator

Wollenhaupt Tee GmbHAlbrecht JUNG automates production in a matter of weeks

Industry

Construction industry

Product

Cartons

Revenue

> €328 million

Challenge

When introducing a new production line, Albrecht Jung GmbH & Co. KG faced the challenge of future-proofing it. Skilled labor shortages, 25-kg boxes, and limited space made implementation difficult. A turnkey robotic cell now automates the palletizing process – quickly integrable, reliable, and strengthening their competitive edge.

Results

Offer to implementation in just a few weeks

Increased production efficiency on 9m²

Ergonomic relief for employees

"Employees don’t need extensive training and can start working at the system after a brief introduction."

Alexander Pfaffenrot, Teamlead

Albrecht JUNG GmbH & Co. KGOptimized palettizing of 25 kilogram boxes at Agrarshop Online

Industry

Agriculture

Product

Cartons

Revenue

> €12 million

Challenge

At peak times, the seasonal nature of agriculture pushes logistics at Agrarshop-Online.com GmbH to its limits. Particularly heavy products weighting up to 25kg place significant physical strain on employees. To avoid bottlenecks and reduce the risk of injury, Agrarshop automated its palletizing process to achieve lasting improvements.

Results

Increased efficiency and throughput in logistics

Minimising the risk of logistics failures and delays

Ergonomic relief for employees

Flexible palletizing of 50 product variants at Avenarius Agro

Industry

Chemical production

Product

Bags

Revenue

> €30 million

Challenge

Heavy construction sacks in varying sizes increasingly slowed down production processes at Avenarius Agro GmbH. At the same time, the ongoing digitalization of the process made it more difficult – and finding suitable personnel was becoming harder. To ensure long-term efficiency, quality, and production safety, Avenarius Agro opted for an automated palletizing solution.

Results

Palletizing of bags on 11m²

Increased flexibility thanks to gripper changing technology

Ergonomic relief for employees

"We run about 50 different products on this system. The easy and quick changeover capability makes the robotic cell a real asset to our production."

Martin Bohmair, Production Manager

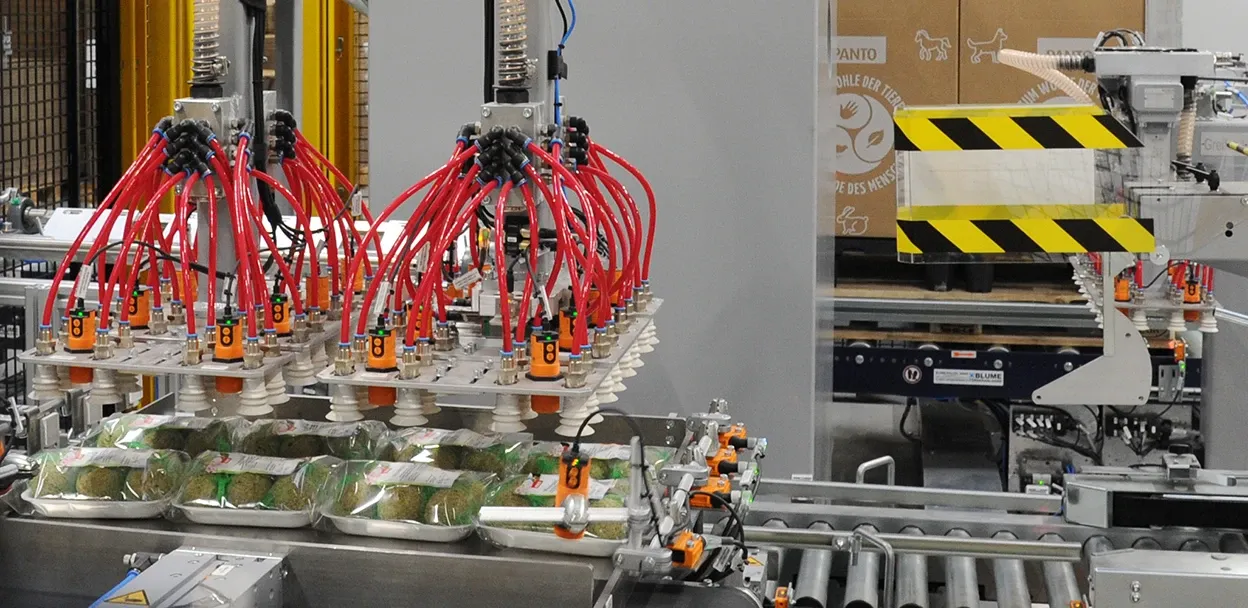

Avenarius Agro GmbHProduction automation enables 1 million products at Eggersmann

Industry

Animal feed production

Product

Trays

Revenue

> €72 million

Challenge

To produce up to one million birdseed balls per day, Eggersmann GmbH needed a solution beyond manual processes. Labor shortages and rising demand made automation unavoidable. Today, a turnkey robotic cell ensures smooth and fully automated palletizing, improving both efficiency and scalability.

Results

Increase in production to one million products per day

Increased production efficiency

Automation of the palletising and packaging line

"I was looking for a solution and an integrator who speaks my language and can propose a solution as quickly as I’m used to. With manual labor alone, the planned throughput simply wouldn’t have been possible."

Heinrich Eggersmann, Managing Director and Owner

Eggersmann GmbHThroughput boost via palletizing automation at Stockmeier Food

Industry

Food production

Product

Cartons

Revenue

> €360 million

Challenge

Stockmeier Food GmbH & Co KG faced the challenge of meeting rising production demands without overloading the space in the production hall. Manual palletizing of the 5-kg units was time-consuming and error-prone, affecting quality. The decision to automate was made quickly: With the coboworx robotic solution, accuracy and throughput were increased while minimizing space requirements.

Results

Increase in production capacity

Space-saving integration into the production environment

Ergonomic relief for employees

"The system runs flawlessly, and even in distant Hungary, solutions were found quickly. I can only report positively and am confident that we will continue to rely on coboworx in the future."

Jan Uwe Wilms, General Manager und Export Manager

Stockmeier Food GmbH & Co KG20% efficiency increase without investment at Lay Gewürze

Industry

Food production

Product

Buckets

Revenue

> €9.5 million

Challenge

The shortage of skilled labor made it increasingly difficult for Lay Gewürze GmbH to attract staff for its 2- to 3-shift operations. Rising hygiene standards and process complexity led to efficiency losses, while manual lifting of 25-kg containers placed a heavy physical strain on employees. The decision to choose a turnkey palletizing solution was therefore obvious: quickly deployable, user-friendly without prior knowledge, and with low investment costs.

Results

20% efficiency increase

Increased flexibility and precision in production

Ergonomic relief for employees

"I looked at the production schedule and said: If we’re doing this, we’ll commission the machine while we’re still producing. It turned out to be one of the quickest machine commissions I’ve ever experienced."

Michael Fischer, Operations Manager

Lay Gewürze GmbHAutomated palletizing of 40kg canisters at Wocklum Chemie

Industry

Chemical production

Product

Canisters

Revenue

> €323 million

Challenge

Wocklum Chemie faced the challenge of automating the manual palletizing of canisters to meet rising production demands. The existing process was time-consuming, inefficient, and placed a high physical strain on employees. The decision was made to implement an automated solution – with the goal of increasing efficiency, relieving employees, and deploying human resources more effectively.

Results

Optimization of working conditions for employees

Increased efficiency of the palletizing process

Positive ROI through monthly rental price

"The system's HMI is easier to use than a mobile phone. You can learn it really quickly."

Mike Schulz, Plant Operator

Wocklum ChemieEmployee relief of 48 tons per shift at Pro Pet Koller

Industry

Animal feed production

Product

Cans

Revenue

> €15 million

Challenge

Pro Pet Koller GmbH faced the challenge of bridging staff shortages while responding to growing demand. The existing palletizing process was time-consuming and increasingly inefficient due to rising complexity. The solution: a compact robotic cell that integrated seamlessly into the existing production line – without requiring additional space or disrupting workflows.

Results

Throughput increase to 800 units per hour

Compact robot solution on 9m²

Ergonomic relief for employees

"We palletize up to 48 tons per shift. Our employees are very grateful that the robot supports them and has taken over the physically demanding work. The whole process has started very positively, and we are very satisfied."

Markus Koller, Managing Director

Pro Pet Koller GmbHPalletizing solution in a flexible Robotics-as-a-Service model at Sirl

Industry

Logistics

Product

Cartons

Revenue

> €34 million

Challenge

Sirl Interaktive Logistik GmbH faced the challenge of ensuring on-time delivery and flexibility for export orders. Manual palletizing of the 18-kg cartons proved to be too slow and inefficient. With the mobile "Basic Move" robotic cell from coboworx, throughput was reliably increased, space requirements were reduced, and the error rate in production was significantly lowered.

Results

Increased flexibility and efficiency

Compact robot solution on 6m²

Installation and commissioning within 2 days

"From the offer to the final decision, it took us two weeks internally. Once we knew we could run 400 units per hour, the robot could handle the 18 kg weight, and we could rent the solution monthly, we were convinced."

Konrad Götz, Head of warehouse logistics and production

Sirl Interaktive Logistik GmbHThroughput boost for just €2,080 per month at SMB Feldner

Industry

Special machine construction

Machine

POS Mill C800

Company Size

5 employees

Challenge

SMB Feldner faced the challenge of processing small batches efficiently while maximizing the utilization of their high-value machining centers. Orders were often declined due to a lack of staff for constant machine loading and unloading. A flexible cobot solution now automates loading and unloading – quick to deploy, mobile, and fence-free.

Results

Extended production runtime

No upfront investment thanks to rental option

Improved workplace safety

“The robot solution is an absolute dream. Any manufacturer dealing with more than two complex parts can easily let the robot run overnight. And the option to rent the system – that’s a huge advantage.”

Thomas Feldner, Graduate Engineer and CEO

SMB Feldner